Many manufacturers already process their carbide rods in the green phase. The rods are dried and therefore very brittle and fragile. In most cases green machining is done manually by the operator. Due to the health dangers and the high dust generation it is necessary to automate this process. The biggest challenge here is in the handling of the fragile rods.

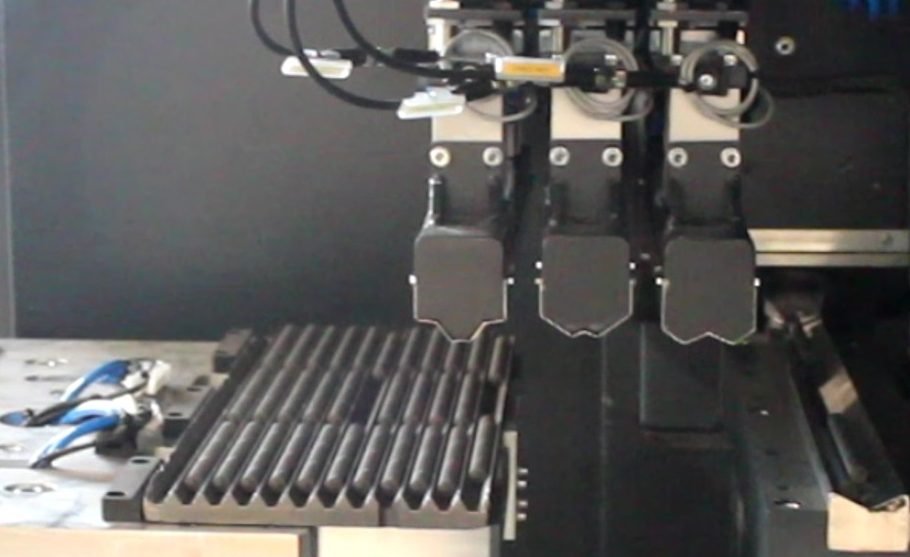

Our specially developed magnetic gate is used here again. The rods are gripped along their entire length by a prism-shaped gripper and moved from station to station. This ensures that the carbide rod is supported over its entire length and does not break.

To feed the rods into the machine, they are taken directly from the graphite plate by the magnetic gate. If desired, the handling of the graphite plate is also done automatically from the drying trolley.

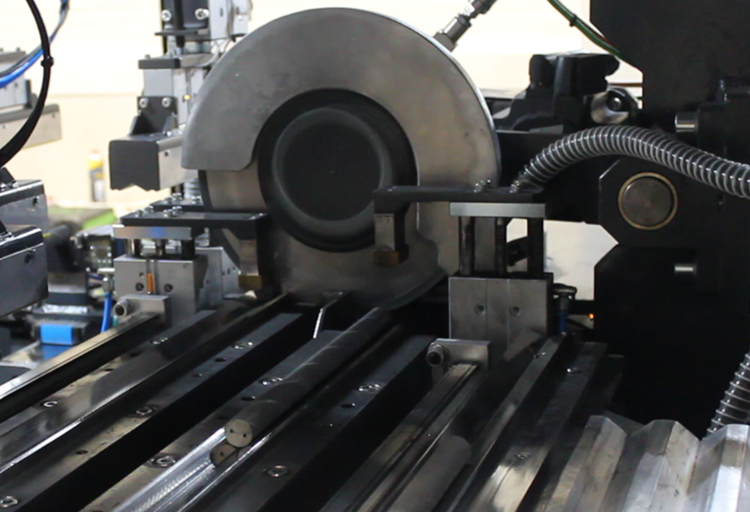

In the first station, the rods are cut to the desired fixed lengths. This is done by a powerful circular saw with a diamond cutting disc. To avoid break-outs during cutting, the saw is equipped with a cutting gap opening. A well-dimensioned dust exhaust system removes the resulting dust. The scrap is collected in a container.

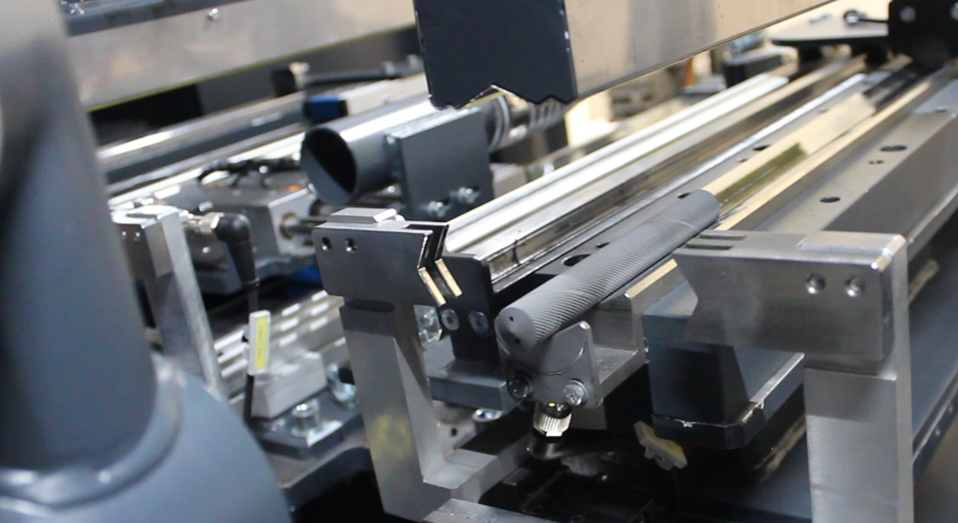

In the second step the tip is milled onto the rod. PCD cutters driven by a milling spindle are used for this. Before milling, the rod is aligned and measured for length so that the rod length can be corrected by milling. In the same way, a chamfer can be milled on the opposite end of the rod.

Furthermore, a disc cutter can be integrated into the system to connect the cooling channels with a slot. For this, the rod must be turned to the correct position before machining. The cooling channels are detected by a vision system.

At the end of processing the rod is cleaned. The cooling channels are blown out with compressed air nozzles. The outer surface can also be blown off in a continuous process.

The finished rod is placed back into a graphite plate. The rods can be placed in a defined layout in order to make optimum use of the sintering furnace.

The entire green machining process as well as the handling of the green rods is, of course, fully automatic. The graphite plates can also be placed by a six-axis robot.

We are looking forward to supporting you with our expertise and many years of experience in mechanical and industrial engineering.

Apply today to join a young and dynamic company with a focus on modern technology and customer satisfaction.

Data protection | Imprint | T&C | Webdesign by – Werbeagentur Die Gipfelstürmer