Our absolute expertise is in handling systems for the production of tubes and rods. In addition to separating devices, our handling systems enable the linking of various systems or their automation. A wide variety of elements of modern mechanical engineering are used. Speed-controlled roller conveyors with coated or hardened rollers, belt conveyors, chain conveyors and driving devices are only a small part of the various possibilities. We always focus on obtaining the greatest possible product protection and increasing your productivity.

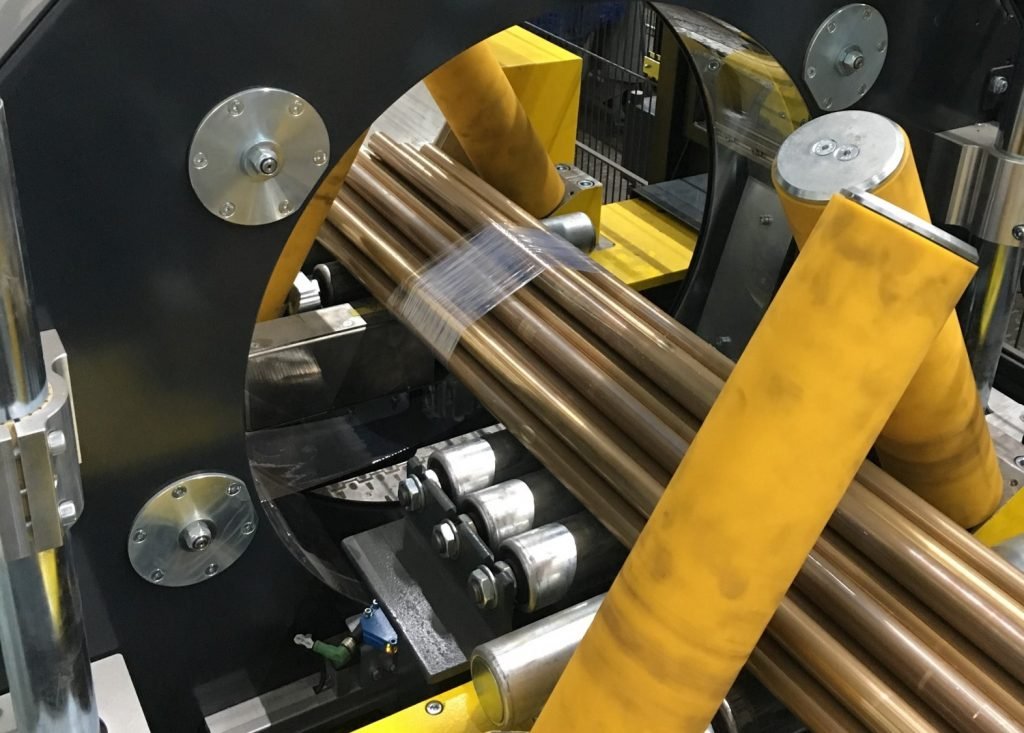

A good example of this is the automation of straightening machines. The infeed takes place via a Vario-channel that continuously adapts to the current tube diameter. While the tube is being straightened, the next tube is already being prepared; dead time is reduced to a minimum. The tube is fed by a tangential roller driver, which drives the tube into the straightening machine and simultaneously sets it in rotation. After straightening, an eddy current test and a non-contact straightness measurement can optionally be arranged.

In general, it is becoming increasingly important to integrate various measuring tasks directly into the production line. For example, tubes can be checked for surface defects before they enter a processing machine where the defects could cause damage. In addition, the diameter and roundness of the tube can be measured in the same way. Through this data, a plausibility check can be made, by which any operator errors can be detected and machine failures prevented.

In almost every machine, it is necessary to collect the finished tubes and rods. For this process, we usually use belt troughs which are designed round or hexagonal. To protect the product, the belts lower automatically depending on the degree of filling. The products can then be wrapped with foil or plastic strapping. For this purpose, we integrate strapping machines from renowned suppliers.

We offer a special form of handling device for cleaning tubes. The system is used mainly behind the cold pilger mill for cleaning stainless steel tubes. We develop individual solutions for your requirements. Optionally also with integrated saws and measuring tasks.

We can also offer individual solutions for feeding roller furnaces. Layers are formed automatically which are then lifted into the feeding roller furnace. At the outlet, the tubes are collected in bundles again. Optionally, the belt trough can also be made mobile so that it can be brought to a central logistics point in the plant.

During the construction and design of the components, attention is paid to temperature resistance.

We are looking forward to supporting you with our expertise and many years of experience in mechanical and industrial engineering.

Apply today to join a young and dynamic company with a focus on modern technology and customer satisfaction.

Data protection | Imprint | T&C | Webdesign by – Werbeagentur Die Gipfelstürmer