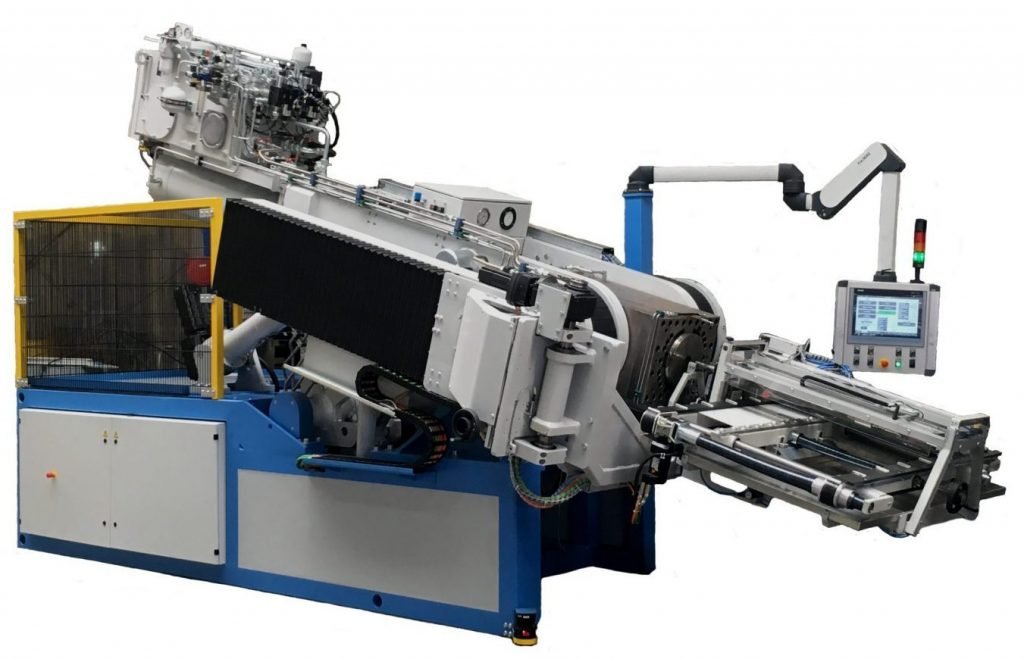

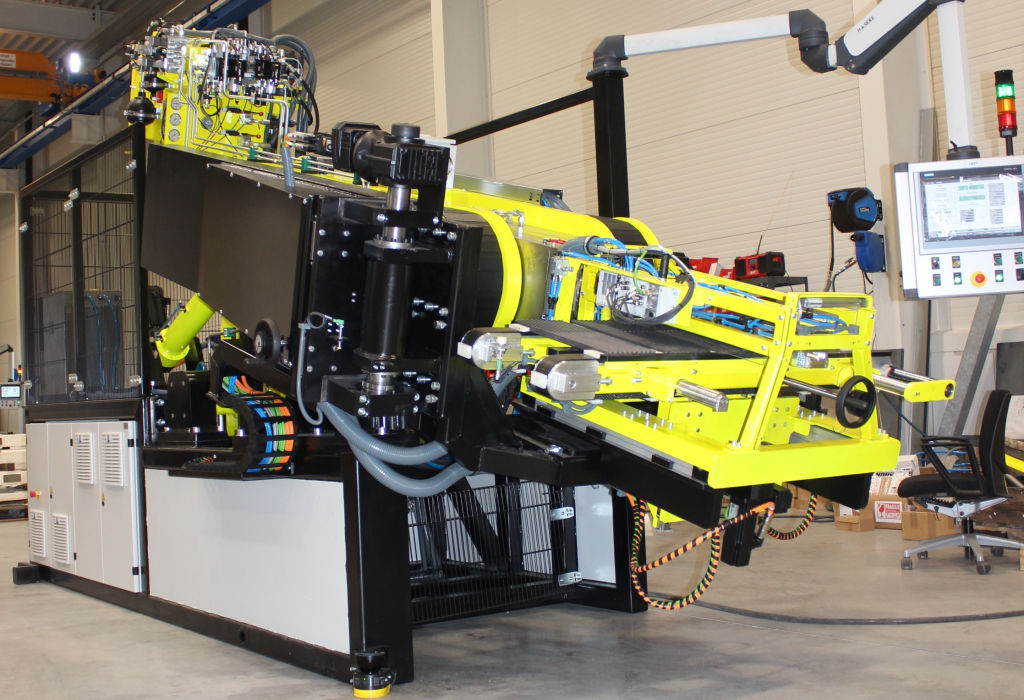

We have worked in the field of carbide production with rod manufacturing for over 30 years. We now offer an extensive array of production machines that interlock seamlessly. Therefore, we deliver our piston extrusion presses directly with an onboard cutting and handling system. Only this combination guarantees the highest possible quality of rods, especially during the manufacturing of small diameters, deep-hole drills, and helical drill rods with integrated cooling holes.

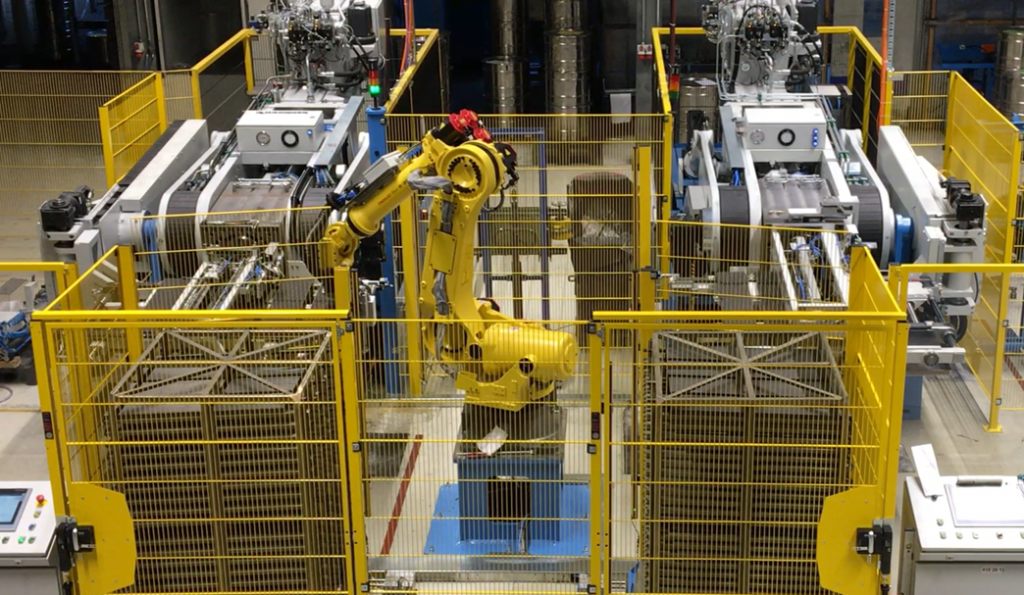

There are no limits to the grade of automation in carbide production. Everything is possible, from a simple, manually operated piston extruder to a fully automatic machine that is filled automatically. The loading and unloading of graphite trays can also be done unmanned. Ideally a six-axis robot handles the filled trays directly into a sinter-carrier which only has to be driven into the oven for the next manufacturing process.

This high degree of press automation makes pressing reproducible and minimises the risk of errors caused by operator influence. This is essential for sensitive carbide material.

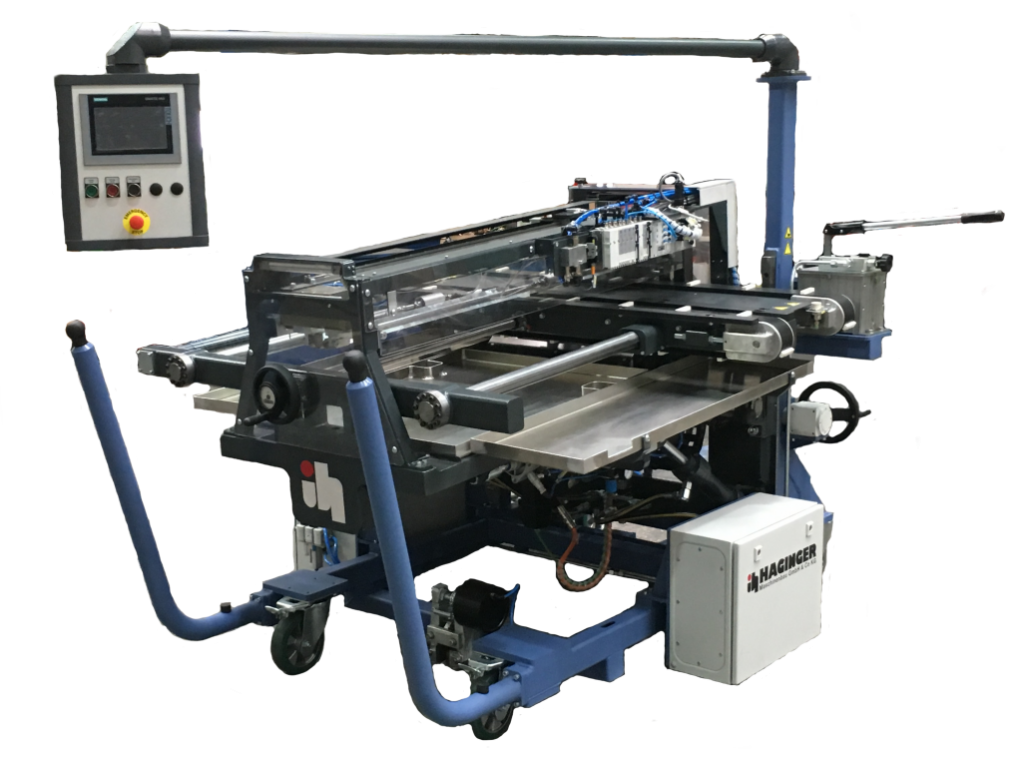

We supply complete solutions with filling and handling systems not only for our extrusion presses, but also for screw presses of various makes. We are thereby able to optimise and improve even existing processes.

With the continuous filling from our specially developed dosing device, the screw extruder can run unmanned for up to one shift with consistent quality.

Our goal is to offer our customers individual solutions that improve their quality and make the process economical. We are constantly trying to develop further and not stand still with old technology. We now also offer machines for testing rods in which the green compacts are measured directly after pressing, e.g. B. whether the straightness of the carbide blanks is OK. Pitch measurement of the helical drills is also possible inline. This enables the detection of false parts at an early stage and the removal of them from the production parts. This saves enormous costs by recycling the carbide rods.

But we can also offer solutions for processing the rods after drying. This includes systems for green processing, which cut, chamfer and clean the bars fully automatically. With these machines, we attach great importance to concepts developed individually to the customer’s requirements.

We are looking forward to supporting you with our expertise and many years of experience in mechanical and industrial engineering.

Apply today to join a young and dynamic company with a focus on modern technology and customer satisfaction.

Data protection | Imprint | T&C | Webdesign by – Werbeagentur Die Gipfelstürmer