The best extrusion press in the world is useless unless it’s combined with the matching handling system. Based on our many years of experience in the handling of carbide rods, we know what it takes to ensure the best possible quality of the rods.

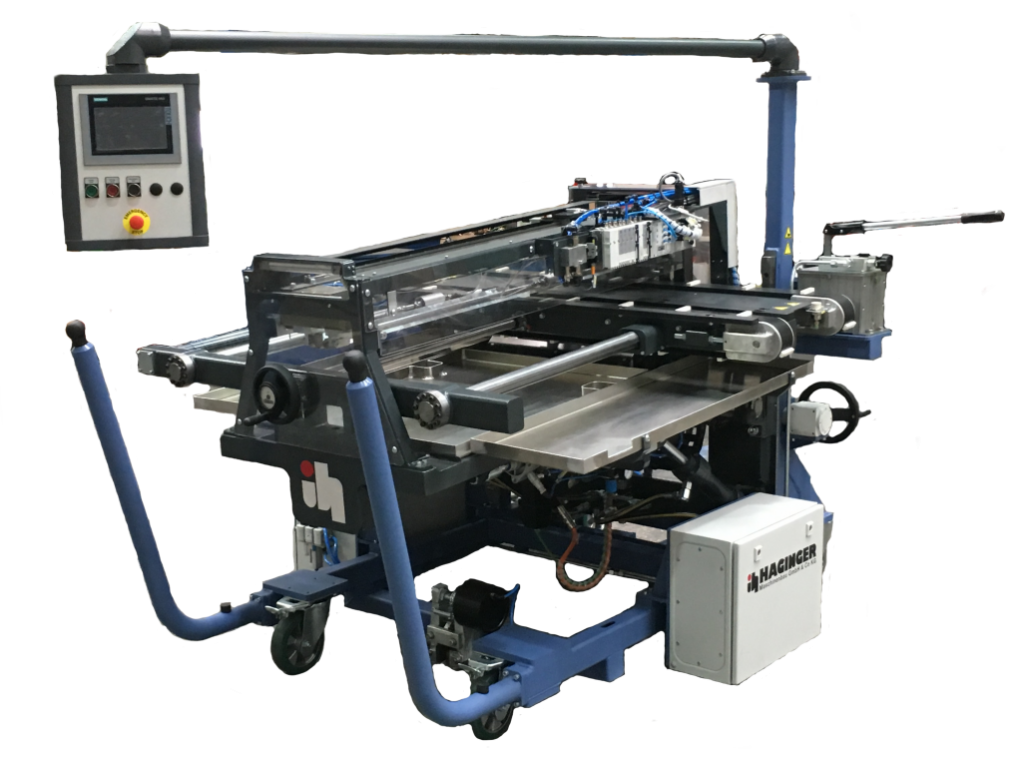

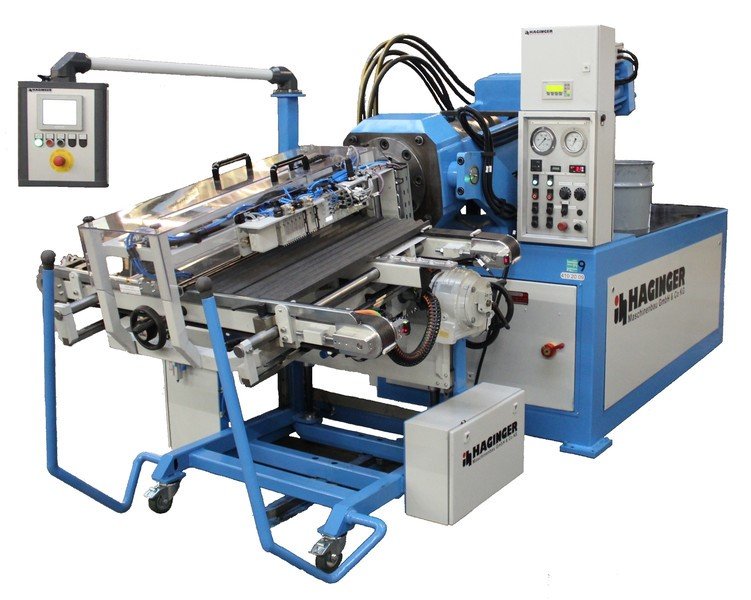

When the handling system is used, it is optimally mounted directly on our piston extrusion press. This gives the best possible alignment and stability during extrusion. For adjustment work, the handling system is automatically swivelled to the side.

We also offer mobile solutions for existing presses or other manufacturers.

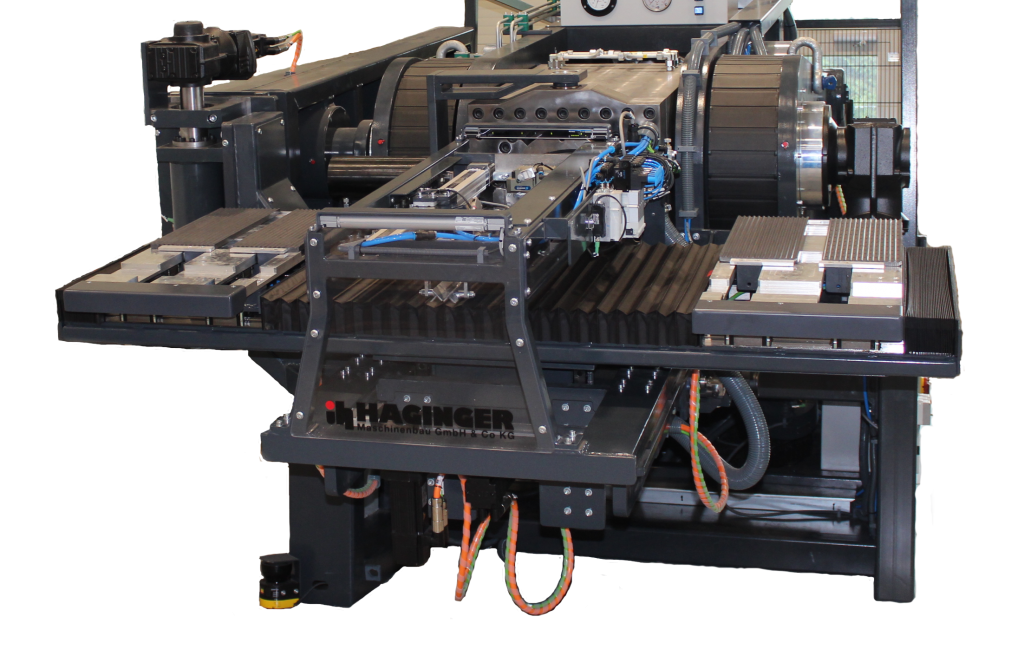

It starts with the outlet channel into which the rods are pressed. The most important thing here is that the rod can slide in the channel without friction, if possible, so that the pitchis not affected. This is done in the classic way with air support or with our specially developed vibration channel. This almost completely eliminates the friction without any effect on the material. Making the system suitable for all carbide mixtures.

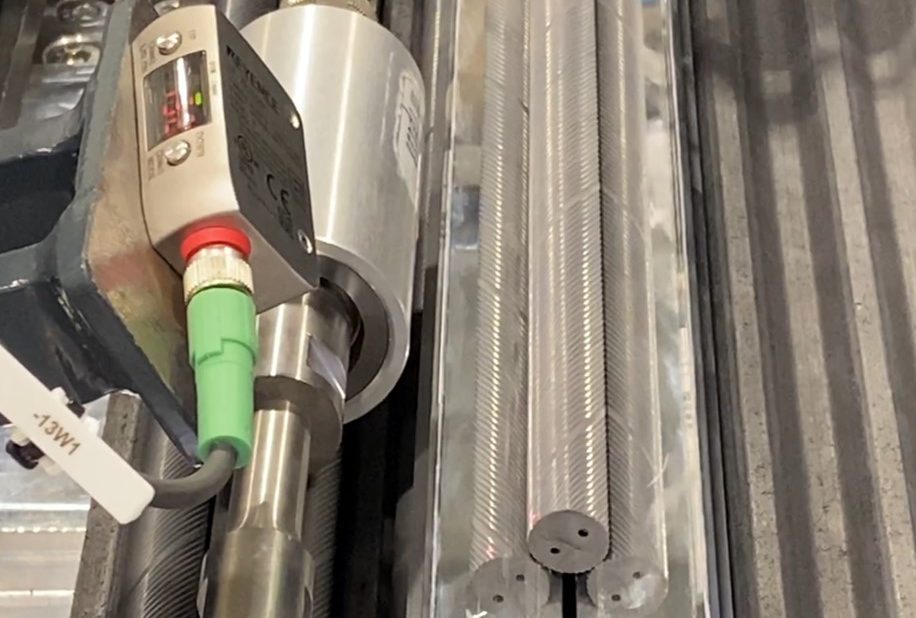

The next important factor is the cutting of the rod. For this, we use flying cutters that cut the rod without compressing or deforming it. The perfect synchronisation between the press and the handling system ensures that the end of the rod is not deformed by the cut. The cut is so precise that the cooling holes are still open and can even be detected with a camera system.

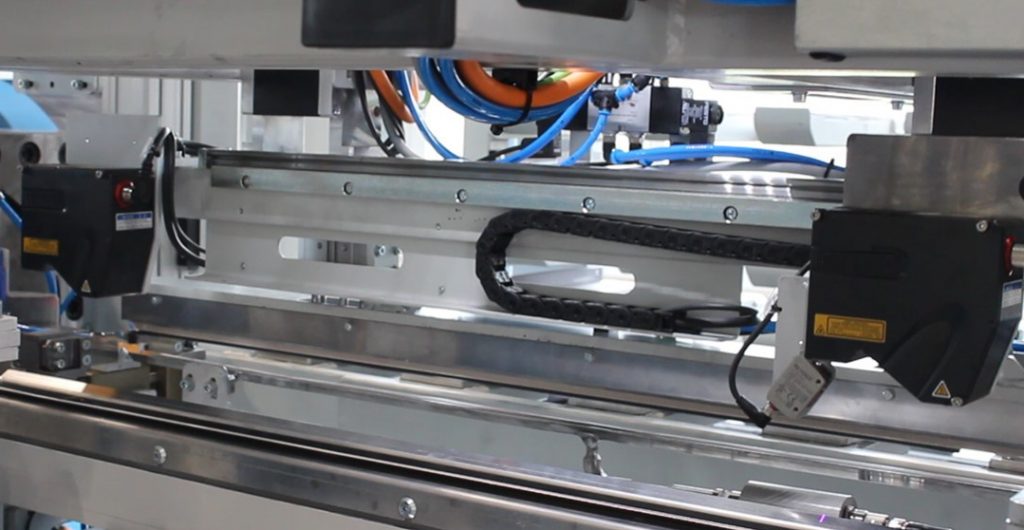

Finally, the cut carbide rod must be placed very carefully onto the graphite plate. This is done by opening the outlet channel or by using a magnetic portal, which has proved especially useful for deep-hole drills. In this process, attention is always paid to ensuring that the rod falls as little as possible and that it is placed precisely in the centre of the groove. With these methods, several rods can also be placed one after the other. Of course, the rod can also be pressed directly into the graphite plate. This makes sense especially forlarge rod diameters or ledges and cutter blocks.

On request, we can also integrate different measuring applications into our handling system, for example, measuring the pitch of twisted rods or measuring the twist of deep-hole drills. Defects are thereby already detectedin the extrusion process and can be sorted out immediately. This has the great advantage that the material can be reused immediately without time-consuming preparation.

We are looking forward to supporting you with our expertise and many years of experience in mechanical and industrial engineering.

Apply today to join a young and dynamic company with a focus on modern technology and customer satisfaction.

Data protection | Imprint | T&C | Webdesign by – Werbeagentur Die Gipfelstürmer